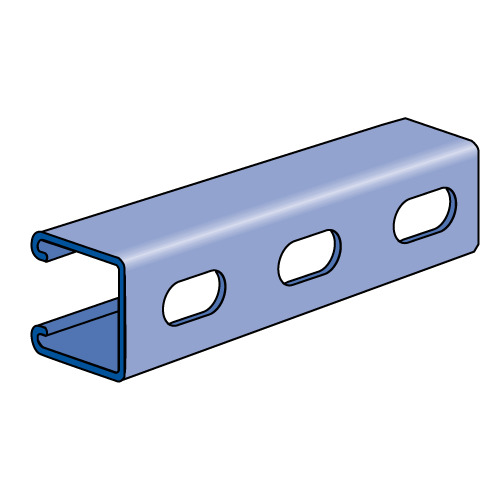

Strut Channel

Filter

34 items

content loaded

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

SKU#:771A1012GHG

MFG#:H132OSX10PG

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

SKU#:202G582OS2PO

MFG#:G582OS2POP

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

SKU#:771A1012GHG

MFG#:H132OSX10PG

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

SKU#:202G582OS2PO

MFG#:G582OS2POP

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.