Safety Tags

Filter

17 items

content loaded

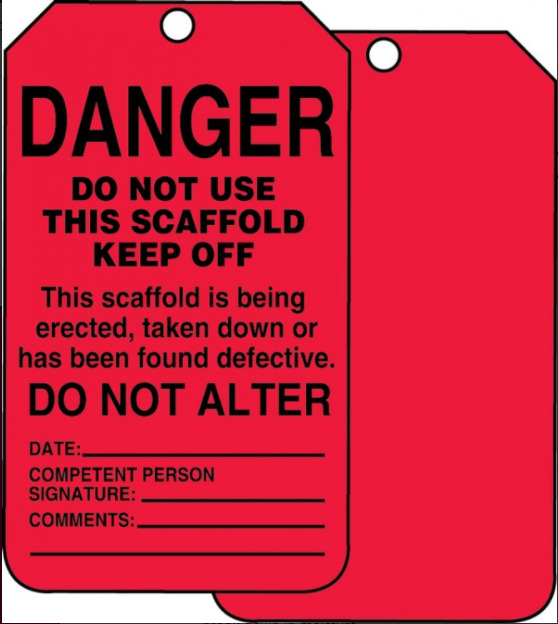

SKU#:333TSS103CTP

MFG#:TSS103CTP

Price

$26.99 (PACKAGE)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

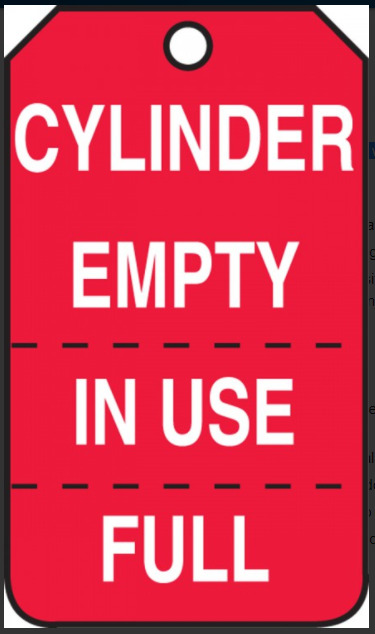

SKU#:333TSS101CTP

MFG#:TSS101CTP

Price

$22.99 (PACKAGE)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

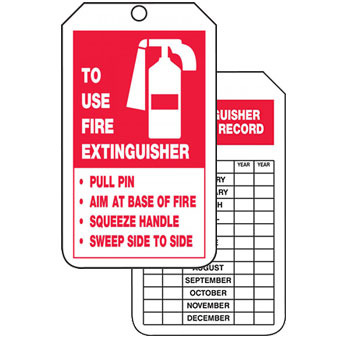

SKU#:333TSS102CTP

MFG#:TSS102CTP

Price

$26.99 (PACKAGE)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

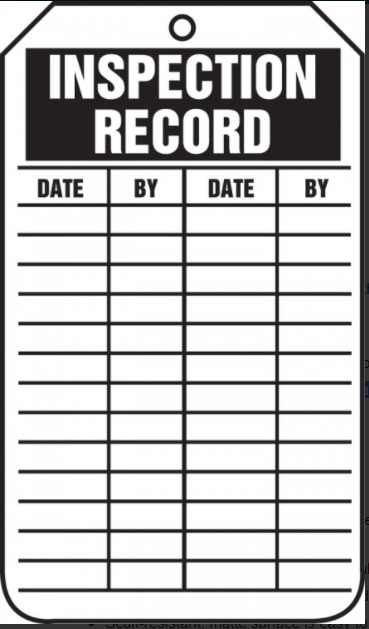

SKU#:333MDT260CTP

MFG#:MDT260CTP

Price

$19.39 (PACKAGE)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

SKU#:333MGT206CTP

MFG#:MGT206CTP

Price

$20.99 (PACKAGE)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

SKU#:333MDT189CTP

MFG#:MDT189CTP

Price

$22.99 (PACKAGE)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

SKU#:333TRS218CTP

MFG#:TRS218CTP

Price

$24.99 (PACKAGE)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

SKU#:333TRS307CTP

MFG#:TRS307CTP

Price

$26.99 (PACKAGE)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

SKU#:333TSS103CTP

MFG#:TSS103CTP

Price

$26.99 (PACKAGE)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

SKU#:333TSS101CTP

MFG#:TSS101CTP

Price

$22.99 (PACKAGE)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

SKU#:333TSS102CTP

MFG#:TSS102CTP

Price

$26.99 (PACKAGE)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

SKU#:333MDT260CTP

MFG#:MDT260CTP

Price

$19.39 (PACKAGE)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

SKU#:333MGT206CTP

MFG#:MGT206CTP

Price

$20.99 (PACKAGE)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

SKU#:333MDT189CTP

MFG#:MDT189CTP

Price

$22.99 (PACKAGE)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

SKU#:333TRS218CTP

MFG#:TRS218CTP

Price

$24.99 (PACKAGE)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

SKU#:333TRS307CTP

MFG#:TRS307CTP

Price

$26.99 (PACKAGE)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.