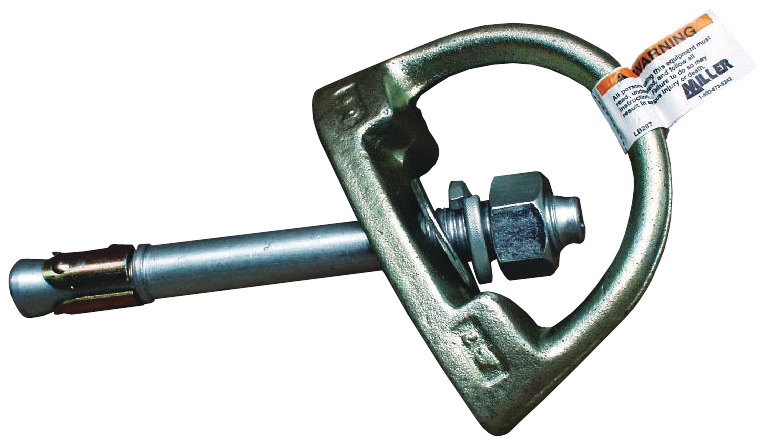

Anchor Points and Connectors

Filter

156 items

content loaded

Price

$162.99 (EACH)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Price

$39.59 (EACH)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Price

$126.49 (EACH)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Price

$19.99 (EACH)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Price

$26.19 (EACH)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Price

$414.99 (EACH)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Price

$181.99 (EACH)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Price

$126.29 (EACH)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Price

$162.99 (EACH)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Price

$39.59 (EACH)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Price

$126.49 (EACH)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Price

$19.99 (EACH)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Price

$26.19 (EACH)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Price

$414.99 (EACH)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Price

$181.99 (EACH)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Price

$126.29 (EACH)

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.