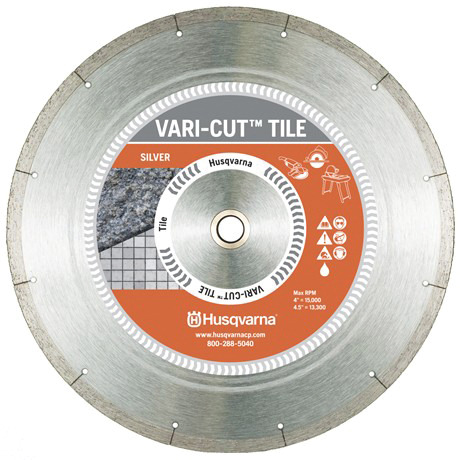

Diamond Cutting Blades

Filter

206 items

content loaded

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.

Item pricing and delivery options may vary based on location. Select your local branch for best pricing.